Custom Mil-Spec Defense Products

Titanium Fabrication Corporation (TiFab) is a trusted provider of NAVSEA military grade titanium product fabrication services for critical defense and naval programs. With decades of experience fabricating high-performance components from titanium, and specialty nickel alloys, TiFab delivers precision products that meet the most rigorous military and marine standards.

Our work adheres to NAVSEA S9074-AQ-GIB-010/248, NAVSEA S9074-AQ-GIB-010/278, and NAVSEA S9074-AQ-GIB-010/271 specifications, ensuring every part is built to exacting code and field-ready reliability.

Fully Equipped for Defense-Grade Fabrication

TiFab’s capabilities are tailored to support the U.S. military, naval shipbuilders, and defense OEMs with advanced material handling, welding, and machining expertise. We operate two ASME-certified facilities with the ability to fabricate, inspect, and ship complex components used on aircraft carriers, submarines, surface ships, and deep-sea systems. Our teams are experienced in producing pressure vessels, pump housings, impellers, sonar system components, and welded structural assemblies—all built using military grade nickel product fabrication and titanium processes that conform to critical NAVSEA standards.

Military-Approved Alloys and Capabilities

TiFab works exclusively with corrosion-resistant, high-performance materials essential to military and marine performance. We routinely fabricate and machine parts using:

- Titanium (Grades 2, 5, 23, and 32)

- Monel®

- Inconel® 600 and 800 Series

- HY-80

- HY-100

These alloys are ideal for seawater resistance, high-strength weight-sensitive structures, and long-term performance in extreme operating environments. Our military specific fabrication processes include full traceability of material, documented weld procedures, and on-site inspection using advanced equipment such as FARO Arm CMM.

Built to NAVSEA Code

Fabricating for the defense industry means working to exacting code and procedure. TiFab has a NAVSEA approved Global Fabrication Plan, and our welding procedures are certified to:

- NAVSEA S9074-AQ-GIB-010/248: Requirements for Welding and Brazing Procedure Qualification

- NAVSEA S9074-AQ-GIB-010/278: Requirements for Welding and Brazing Personnel Qualification

- NAVSEA S9074-AQ-GIB-010/271: Fabrication and Inspection of Submarine Structures

Every project includes shipyard approved weld procedures and PQRs, shipyard approved NDE procedures, engineered fixtures, and material certification. TiFab’s history includes fabricating equipment used on every active U.S. aircraft carrier and submarine since the mid-1990s, as well as custom components for deep-submergence systems like the Alvin submersible and remotely operated rescue vehicles.

Defense Projects We Support

Our team brings value to naval projects with responsive engineering support and a deep understanding of the end-use conditions our components must withstand. TiFab routinely supports the fabrication of:

- Submarine and carrier pump casings

- Titanium impellers and housings for fluid systems

- Structural frames and plates for deep-sea equipment

- Welded titanium and nickel piping spools

- Sonar and guidance system enclosures

- Custom pressure vessels and military-grade containers

Each of these products is built using processes tailored to military grade nickel product fabrication and titanium techniques that preserve material properties while ensuring long service life in aggressive conditions.

Why Defense Contractors Rely on TiFab

TiFab’s commitment to military-grade standards goes beyond welding and machining. Our team partners closely with engineers and procurement officers to ensure specifications, documentation, and delivery timelines align with critical mission objectives.

- Over 50 years of titanium and nickel alloy fabrication expertise

- Full in-house welding, machining, waterjet cutting, and inspection

- NAVSEA-qualified welders and procedures

- Responsive quoting and production schedules for urgent defense needs

- Metal service center for DFARS compliant titanium raw material supply

We also offer mobile field welding services to support on-site repairs, retrofits, and final assembly for defense platforms worldwide.

Trust Us to Support Your Defense Fabrication Needs

If your program requires dependable NAVSEA military grade titanium product fabrication, TiFab is ready to deliver. Our team understands the pressure of shipyard schedules, the complexity of code-compliant fabrication, and the demands of the environments where these products are deployed.

To request a quote, discuss material selection, or schedule engineering support, contact TiFab today. We’ll help ensure your military fabrication project moves forward with precision, compliance, and confidence.

Titanium Welded Assemblies

Titanium Fabrication has welded assemblies on every U.S. nuclear submarine and air craft carrier built in the last 20 years.

Learn More

Nickel Alloy Welded Assemblies

TiFab has been a trusted partner with the U.S. Navy shipbuilding contractors for over 30 years.

Learn More

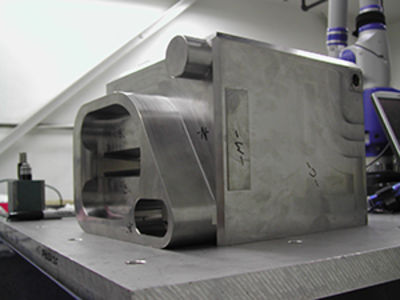

Machining of Custom Navy Components

In addition to our world renown welding expertise, TiFab also has best in class machining capability for titanium and nickel alloy marine components.

Learn More

Weld Repair of Castings & Rotating Equipment

TiFab has all the necessary TIG titanium and zirconium welding procedures approved for NAVSEA Tech Pub requirements, or for ASME code requirements.

Learn More